Hank

Our factory has an excellent and stable production supply chain, and each supplier has been strictly audited by Hanke and has cooperated with us many times

Hanke has a strict incoming material quality control system, in order to ensure the quality of products, as a leader of mobile phone accessories, we have established a complete team composed of technical engineers, procurement, IQC, PMC, warehouse management personnel, transportation, etc., multi-dimensional management experience to integrate automated production line equipment, reasonable staff layout is the main part of successful production. These include not only reducing production costs, but also relying on savings in customer procurement costs to speed up delivery. In addition, it controls every step of production to ensure the efficiency and stability of production.

※Has 26 product assembly lines

※The factory covers an area of 20000 square meters

※Has 24 product assembly lines

※The factory covers an area of 14000 square meters

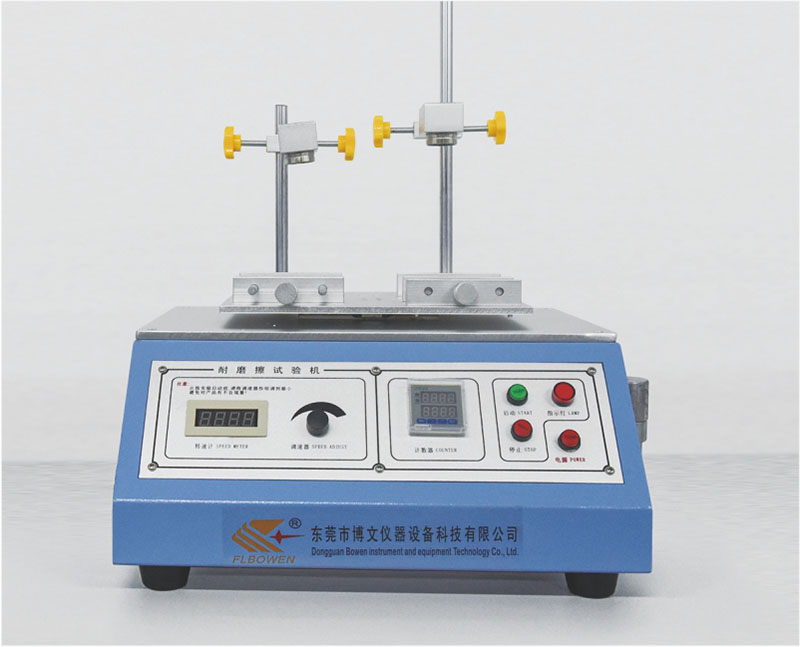

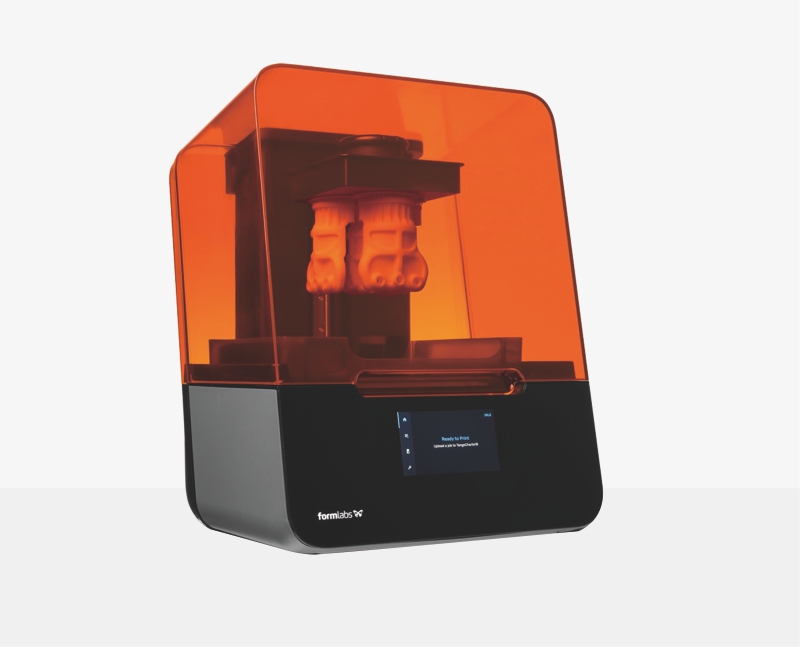

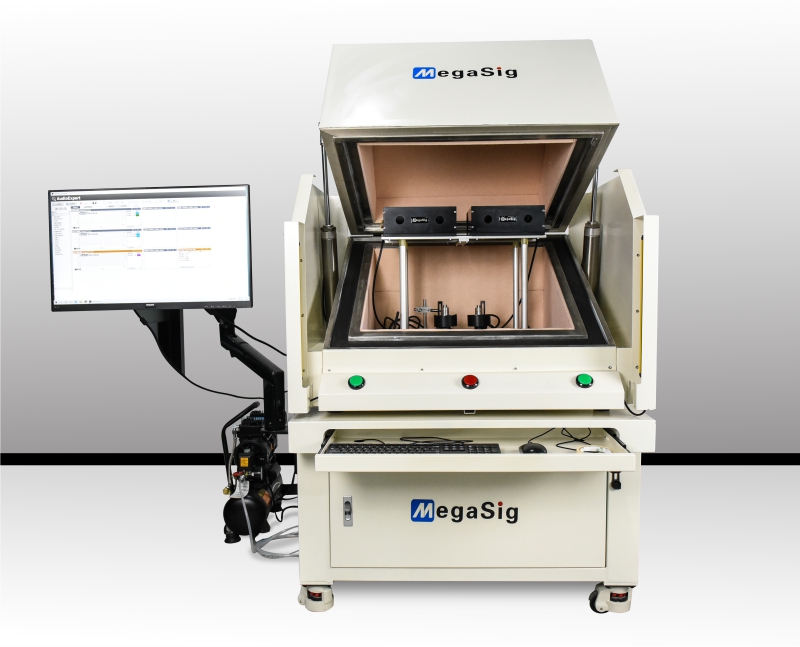

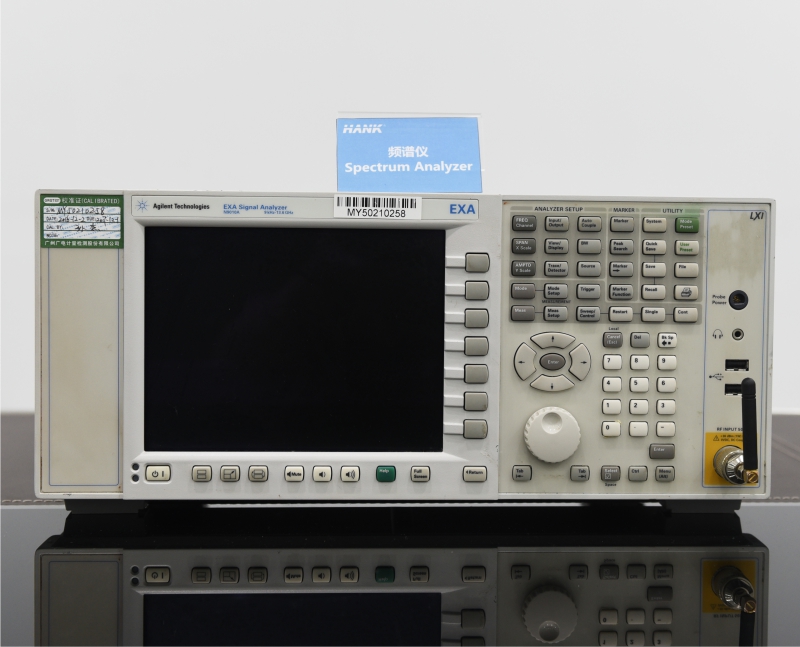

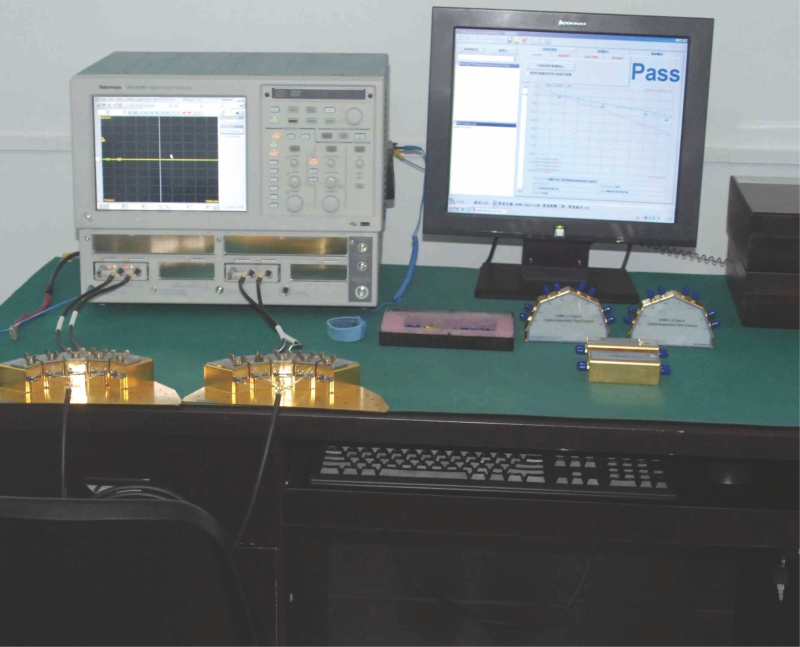

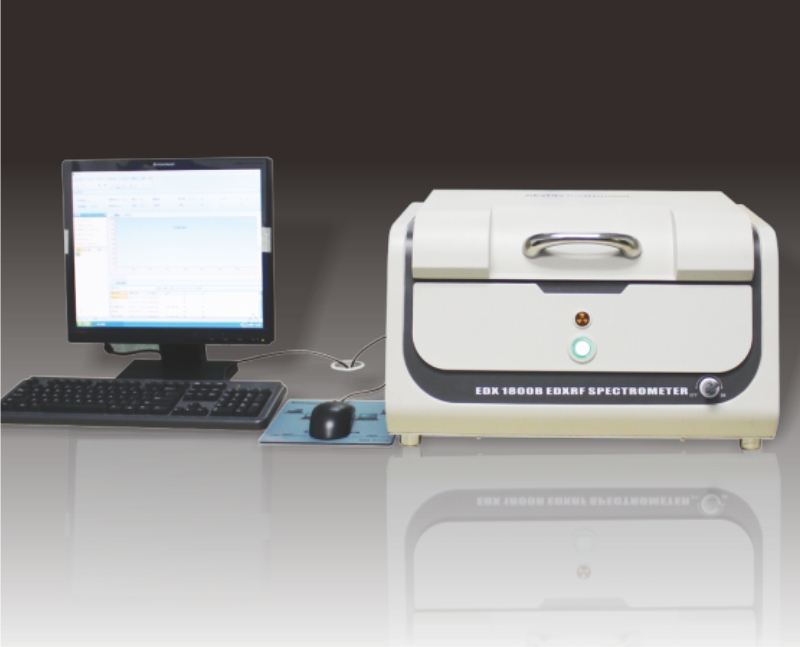

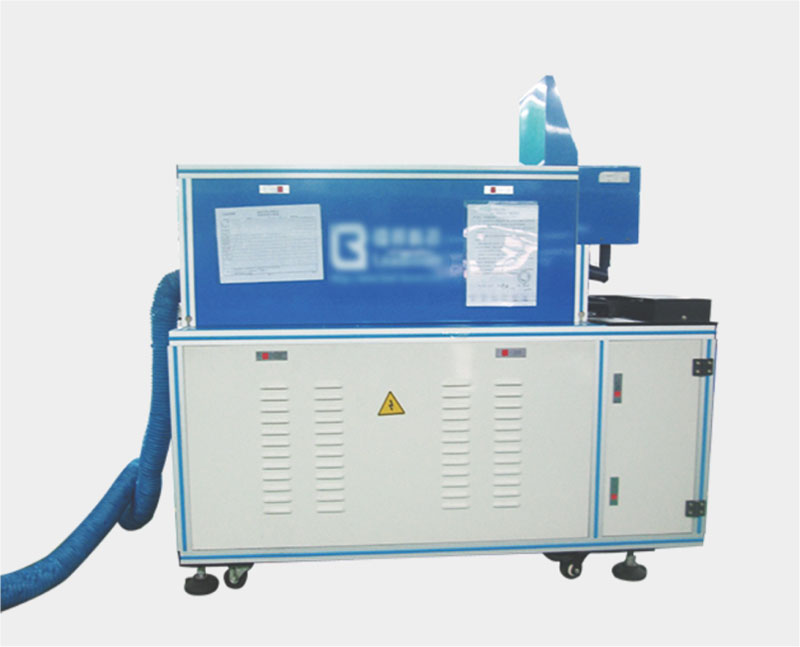

The in-house laboratory is equipped with a diverse array of instruments for comprehensive testing, including drop testing, salt spray testing, vibration testing, simulated transport testing, embedding testing, vertical combustion testing, as well as both horizontal and vertical high and low temperature testing.

Hanke has a complete and perfect wire technology product system such as Micro cable, audio cable, TYPE-C cable, in addition to the product line has expanded to power supplies, headphones and smart home devices

■ Independent in-house laboratory to do some basic tests such as: drop test, salt spray test, vibration test, simulated transport test, embedding test, vertical combustion test, horizontal vertical test, high and low temperature test

■ Fully automatic aging equipment to improve production efficiency

■ Spacious testing lab for audio and power products

■ 26 assembly lines and 14,000 square meters of plant space